Frequently Asked Questions

Why Clay Pipe & NCPI

Material Properties of VCP

Sustainability

Operations & Maintenance

Installation & Inspection

Design

Trenchless Technologies

NCPI is a research institute. We value our position in the civil engineering community as a source of reliable, trustworthy information.

The findings of various research projects conducted by NCPI have led to the continuous improvement of VCP. Some of the more consequential changes include improvements to the pipe bodies, the joints used, the installation methods employed, and the long-term operations and maintenance of installed pipelines. Our education outreach is designed to share what we’ve learned and how it has been applied to industry standards.

We understand how minor “choices” about the information presented can be misleading. We very intentionally endeavor to avoid any manipulation of facts in favor of presenting engineers, municipalities, maintenance professionals and contractors with the facts needed to make fully informed decisions. We believe this is critical to the long-term benefit of the sanitary sewer industry as a whole and to the slice of that industry represented by our Member Companies.

Long-term thinking on multiple fronts drives specifications for VCP, including:

- Material properties

- Sustainability

- Operations & Maintenance

- Service life

All of these combined result in a superior ROI.

Material Properties

Vitrified clay products are kiln-fired ceramics with everlasting material properties unaffected by age, light, or chemicals. On the flip side, limited life products made from plastics “dry out” and become brittle, due to their long chains of molecules, weeping plasticizers as the material ages.

Sustainability

In this case, sustainability is built from both the service life and from the raw materials and processes used to make the pipe. VCP is made from clay, shales, and water, so it is a non-oil-dependent material. VCP offers both an EPD and an HPD.

Operations & Maintenance

VCP stands up to both chemical and mechanical cleaning methods and has for over 100-years. VCP allows municipal maintenance departments greater flexibility when using high-pressure nozzles, mechanical cleaning tools, and odor control chemicals.

Service Life

Only VCP can document more than 200-years of service in the U.S., 400 – 500 years in Europe, and thousands of years of service throughout the world. VCP will not rust, corrode, shrink, elongate, bend, deflect, erode, oxidize or deteriorate over time.

Vitrified Clay Pipe (VCP) has been in use for gravity sanitary sewer systems for at least 6,500 years. That level of experience is unmatched and unrivaled in sanitary sewers of any era. Five of the six largest U.S. cities continue to specify and use Vitrified Clay Pipe for gravity flow sanitary applications. There are several reasons why, but the primary reason is that municipalities and engineers are confirming the superior long-term value based on the long life and low maintenance of the product. They test competitive products, evaluate the results, and opt to specify VCP – both for what it has been for thousands of years and for what it has become: the best long-term value for sewer pipe.

In the more than 200-years since clay pipe was introduced in the sewers of major U.S. cities, ASTM standards have been adopted that require the pipe bodies to meet stringent strength metrics. Leak-free compression joints have been developed, and a multitude of installation practices have been tried, tested and adjusted or discarded.

ASTM was created and the clay pipe industry formed the C04 committee that eventually created the first specification for sewer design and construction. Prior to the acceptance of this standard, thousands of miles of clay sewer pipe of radically varying quality were laid using dramatically varying methods.

In the more than 100-years since the first standard was accepted, additional standards for pipe strength, testing procedures and joint performance have all been proposed and accepted, so that today’s VCP joints “shall not leak.”

For over a century, since the inception of standards for manufacturing and installing pipelines, clay pipe manufacturers have led the way. Some of the high points include:

- The first ASTM Committee established for standard specifications and tests in the sewer pipe industry

- The first Memoranda of Recommendations for the Laying of Sewer Pipe was led by Anston Marston as part of ASTM Committee C04

- The first bell & spigot joint (even before joints were factory-applied)

- Led development of the compression joint in the 50s

- Developed the Low-Pressure Air Test for acceptance testing in the 70s

- Conducted extensive testing on CLSM as a bedding material leading to the Optimal Mix Design published in 2010.

Modern VCP joints do not leak.

Clay Pipe manufactured in the U.S. since the 1950s has durable, factory-applied, flexible, compression joints and couplings that effectively eliminate water leakage while providing the needed flexibility. Misinformation about leaking joints is attributed to the long service life of clay pipe installations of well over a century in service. Clay pipe installations over 70 years old may have field-manufactured joints that do not meet current standards. All factory-applied clay pipe jointing systems, whether on bell-and-spigot pipe, plain-end pipe, or jacking pipe are designed to provide resilience and flexibility to accommodate minor pipe movement while maintaining a strong, leak-free joint.

All current jointing methods for VCP meet the prerequisite of ASTM C425, which requires that the joints not leak when subjected to both shear load and deflection.

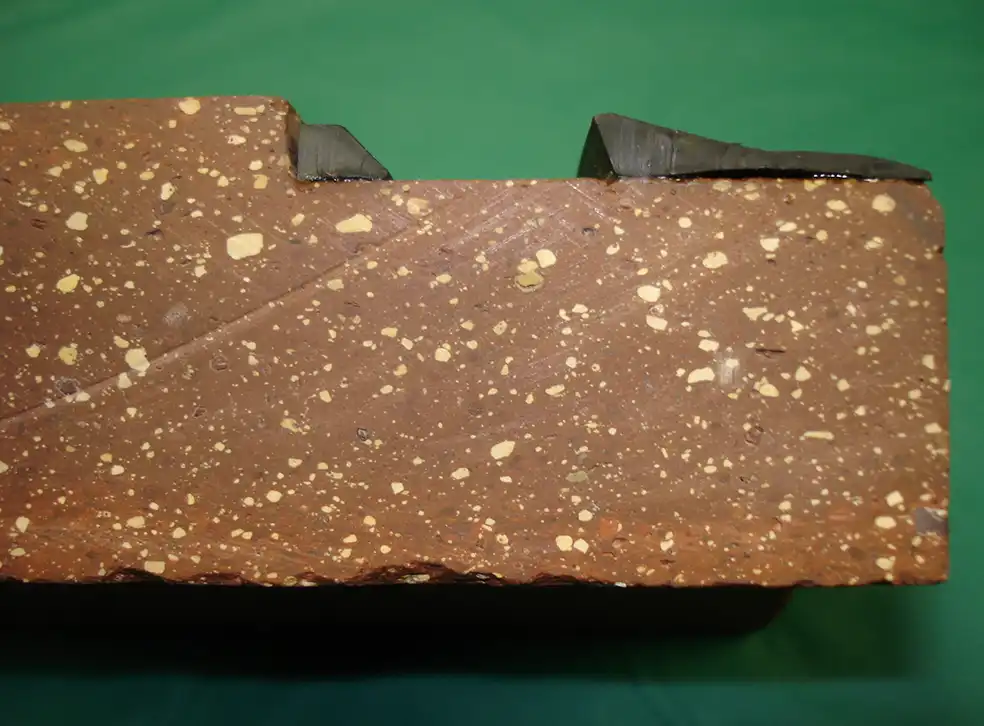

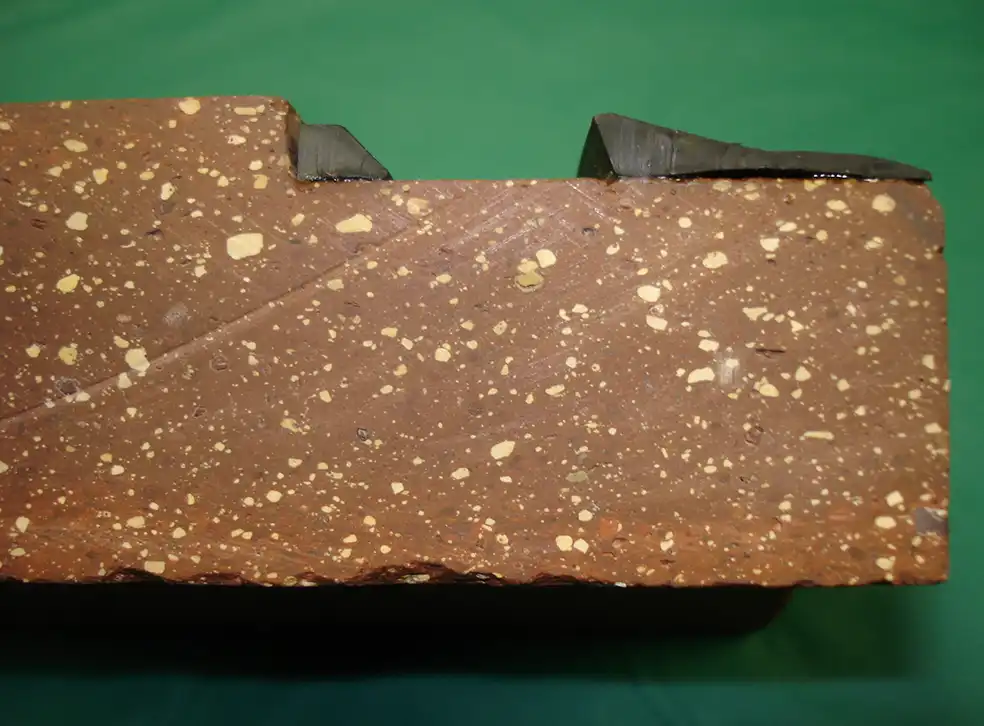

Clay pipe manufactured before the 1950s may not be fully vitrified and may also have laminations within the body of the pipe, both resulting in lower strengths.

The term “vitrified” refers to the fired state of a ceramic. Vitrified clay has been fired at temperatures of approximately 2000°F (1100°C) to make it very strong, hard and dense. At this temperature, vitrification occurs as the clay mineral particles become fused into a chemically inert and stable material. Today’s Clay Pipe has high bearing and compressive strength and is unique in its corrosion and abrasion resistance.

Today’s clay pipe VCP is manufactured to a three-edge-bearing strength specification, not overall dimensional criteria. ASTM C700 provides manufacturing dimensional tolerances as well as minimum three-edge bearing strengths. Wall thicknesses vary by pipe size and manufacturer. Please contact the pipe manufacturer to get specific information.

It is difficult to get dimensional information for older pipe. A number of manufacturers are no longer in business and it can be very difficult to identify which manufacturer made a given pipe.

VCP holds up very well in seismic zones. The short lengths (as compared with other materials) and flexible compression joints work together to survive both angular deflection and shear forces created by the lateral waves. VCP sections do not deflect or deform with loading changes. The clay pipe manufacturers have been industry leaders in the development of seismic cushions within the joints. Even before the introduction of the seismic cushion, in the few pipelines that have been studied following an earthquake, VCP lines were statistically the most likely to have survived a 7.1 quake.

See Tech Note 26

LA Seismic Study 1974

The factory-applied flexible joint can take angular deflection and a tremendous amount of shear loading which are key elements in pipeline seismic resiliency.

In fires, thermoplastics can be compromised, and they frequently leave behind toxins that can be airborne or stored within the soil. VCP is inert and fired at temperatures of approximately 2000°F in manufacturing. There have been no reports of deformed VCP following forest or urban fires.

Over the life of a clay pipe (from cradle to grave), VCP is unmatched for several reasons.

Raw Materials.

Service Life.

Maintenance.

Greater Resiliency in Floods & Fires.

Financial Impacts.

The calculation of carbon footprints is based on weight. Even with that constraint, the Carbon Footprint of VCP is consistently one of the lowest when including embodied energy and CO2.

For more information about how these values were derived, see Hammond & Jones, 2011.

VCP was an early leader in sustainability, as the first buried infrastructure product independently certified under a third party audited system. Download the Summary or Scorecard for more information about this certification.

See the Resource Allocation section of Envision; VCP will provide credits

NCPI offers a full range of training workshops to meet your group’s needs.

NCPI’s Vitrified Clay Pipe Engineering Manual, ASTM C12, NCPI’s Installation and Inspection Handbook and NCPI’s CCTV Handbook are the best sources of current, published information on installation techniques and bedding classes. The NCPI publications are available online or through our member companies.

If this is your first time to install VCP or if it’s been a few years, we strongly recommend the Installation & Inspection Workshop for your inspectors and contractor’s crew.

To find out more, or schedule a training, contact one of our member companies.

In actual practice in the ditch, NO. Theoretically and mathematically, you would expect it to. When you do the math using a standard buoyancy calculation, the pipe should float. However, in actual practice, the CLSM when placed around the pipe forms an immediate friction between the pipe and CLSM. The theory in support of real-world experience is that friction plus the weight of the pipe prevents the pipe from floating. Tests in the field using two concrete trucks dumping their chutes simultaneously, over the top of the pipe did not cause the pipe to float. That being said, NCPI recommends against placement of CLSM at extremely high discharge rates.

For more information on CLSM: Guidelines for CLSM

Common handling guidelines for all pipe materials generally include: storing the pipe so that the joint-ends are kept out of the dirt and supported from pavement, pipe should be inspected at the time of delivery and again immediately prior to installation, any pipe rejected should not be marked or defaced in any manner.

There is no need to protect VCP from sunlight or heat.

NCPI’s Vitrified Clay Pipe Engineering Manual, ASTM C12, NCPI’s Installation and Inspection Handbook and NCPI’s CCTV Handbook are the best sources of current information on installation techniques and bedding classes. The NCPI publications are available online or through our member companies.

If this is your first time to install VCP or if it’s been a few years, we strongly recommend the Installation & Inspection workshop for your inspectors and contractor’s crew.

Clay Pipe is manufactured to a three-edge bearing strength specification, not overall dimensional criteria. ASTM C700 provides manufacturing dimensional tolerances as well as minimum three-edge bearing strengths. Wall thicknesses vary by pipe size and manufacturer. Please contact the pipe manufacturer to get specific information.

It is difficult to get dimensional information for older pipe. Over the 200+ years that clay pipe has been manufactured in the U.S., several different classes or strengths of pipe have been used, a number of manufacturers are no longer in business and it can be very difficult to identify which manufacturer made a given pipe.

- ASTM C12 Standard Practice for Installing Vitrified Clay Pipe Lines

- ASTM C301 Standard Test Methods for Vitrified Clay Pipe

- ASTM C425 Standard Specification for Compression joints for Vitrified Clay Pipe and Fittings

- ASTM C700 Standard Specification for Vitrified Clay Pipe, Extra Strength, Standard Strength and Perforated

- ASTM C828 Standard Test Method for Low-Pressure Air Test of Vitrified Clay Pipe Lines

- ASTM C896 Standard Terminology Relating to Clay Products

- ASTM C923 Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures, Pipes, and Laterals

- ASTM C1091 Standard Test Method for Hydrostatic Infiltration Testing of Vitrified Clay Pipe Lines

- ASTM C1208 Standard Specification for Vitrified Clay Pipe and Joints for Use in Microtunneling, Sliplining, Pipe Bursting and Tunnels

- ASTM C1920 Standard Practice for Cleaning of Vitrified Clay Sanitary Sewer Pipelines

Yes, it can. Live load computations should be part of the design considerations for bedding and trench backfill at cover depths of 8 ft. or less. For more information about the safety factors associated with a live load and specific bedding classes required to meet those safety requirements, use the Trench Load calculator found in the NCPI Toolbox.

Cover depths of less than 2 ft may require a steel casing, CLSM embedment, or concrete encasement for an adequate safety factor using an HS-25 live load scenario. When in doubt, please contact NCPI for a discussion of your specific challenge.

FOS = (Pipe Strength) x (Bedding Factor) / Anticipated Trench Load. See chapters 4 and 6 of the NCPI Engineering Manual.

Pipe strength can be defined as the minimum three-edge bearing strength per ASTM C700, Greenbook Extra Strength or Greenbook High Strength. Use the Trench Load calculator in NCPI’s Toolbox to enter the pipe size, soil type, planned trench width and depth of cover for a project. Toolbox will do calculations to return safety factors for various pipe standards and bedding classes. The Trench Load calculator can also include considerations for live loads where needed.

When the anticipated trench load requires a bedding factor of greater than 2.8, one of the cementitious bedding classes should be used to achieve the appropriate Factor of Safety for the trench design. These bedding classes are also commonly used to protect the installed pipe from future adjacent utility work or construction even though it is not needed for the trench design.

These cementitious bedding classes could also be used as an alternative to Geotextile fabric wrapped granular bedding to prevent soil migration in fine-grained native soils with fluctuating water tables or where migration is a concern.

The effect of adding surcharge loading or live loading can be computed but the age as well as detailed knowledge of the original construction is very important to accurately estimate the effect of the additional load. NCPI has put together a set of guidelines for evaluation of surcharge conditions.

We can also help with predictive calculations.

Anything below 1.0 for a Factor of Safety indicates a risk of failure.

During trench design for VCP, an FOS between 1.0 and 1.5 is the norm, however an engineer may opt to specify an even greater safety factor based on a risk / reward calculation for a specific project or location.

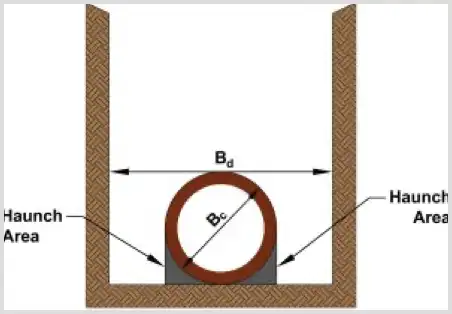

Transition width is the point in the trench where the trench load is equal to the embankment load. Simply put, the load on rigid pipe increases as trench width increases. The transition width is the point beyond which increasing the trench width will no longer add any additional load to the pipe. At transition, the pipe load is at its maximum value. Trench width for any rigid conduit is measured at the top of the pipe barrel.

Trench Width is explained in NCPI’s Vitrified Clay Pipe Engineering Manual and may be calculated using the NCPI Toolbox program. To find out more and to use Toolbox, click here. For assistance using the program or with any special concerns, please contact a member company for local representation.

The Cd coefficient is dependent on the type of backfill material above the pipe (soil prism vertical frictional planes), the trench width (Bd), and the depth of cover (H) but NOT the pipe bedding.

The Cd coefficient is dependent on the type of backfill material above the pipe (soil prism vertical frictional planes), the trench width (Bd), and the depth of cover (H) but NOT the pipe bedding.

NCPI has completed many research projects resulting in methods of installation for VCP in deep applications. Our research, specifically on CLSM (Controlled Low Strength Material) is a solution for structurally supporting open trench VCP in deep installations.

Trenchless installation is also an option for deep burial VCP. Vitrified Clay Jacking Pipe can be installed by either using pilot tube or slurry microtunneling methods. For more information about this method, visit the no-digpipe.com website.

In 1913, when ASTM published the first bearing standard, a 12” diameter pipe (standard strength) was only required to bear 1,200 lbs/LF. As research into Factors of Safety and Bedding Classes evolved, so did clay pipe. Today a 12” diameter, (extra strength) pipe must bear 2,600 lbs/LF.

For a more in-depth review of the changes over the years, explore our Materials Comparison training workshop.

The reasons for selecting a trenchless installation method vary greatly by project, but a few of the most common reasons include: cost of surface restoration, water tables and depth of installation. When a project calls for a trenchless installation method, the Pilot Tube Method is frequently preferred because of the reliably rifle barrel straight line and grade.

Click here to watch an example using the Pilot Tube Method of Guided Boring in Novi, MI.

Vitrified Clay Jacking Pipe has been the predominant pipe material used in the Pilot Tube Method (PTM) process due to the following:

- Its high compressive strength

- A low-profile zero-leakage joint

- Availability in the typical 1- 0r 2-meter pipe lengths

- Elimination of the external casing pipe

Vitrified Clay Pipe has an extremely high compressive strength (18,000 psi average), a feature that makes it uniquely suited to endure the high jacking forces generated as the pipe is pushed through the ground.

In addition to the Pilot Tube Method, Vitrified Clay Pipe has been used for Slurry Microtunneling, Pipe Bursting, and Sliplining.

For more information, visit No-DigPipe.com.

This varies greatly depending upon soil conditions, contractor experience and the selection of the two step or three step process. A rough average for a 300 ft. drive is one week:

- Day one for setup

- Day 2 for installation of the pilot tubes

- Days 3 through 5 for installation of temporary casings and/or product pipe

Quick Links to NCPI Manuals & Handbooks